Getting money from one country to another to build a factory or a big business is called Foreign Direct Investment (FDI). It’s a huge deal for a country’s economy. When a foreign company decides to invest, it brings new jobs, new technologies, and a big boost in cash. Think of it as a global business partnership.

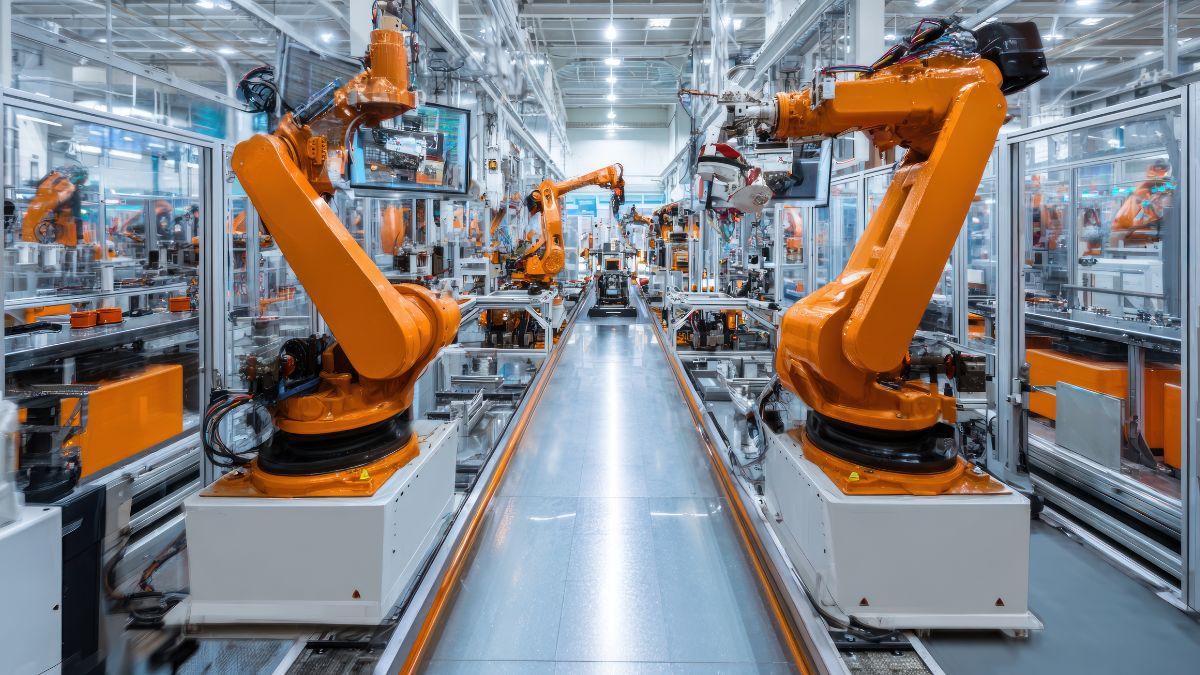

For decades, many companies invested in places that offered the cheapest labor. Now, things are changing. Businesses are no longer just looking for the lowest cost. They are looking for the best value and the smartest place to build their goods. This shift is giving rise to what we call advanced manufacturing hubs. These aren’t just regular factory areas; they are high-tech zones built for the future. They focus on things like robotics, smart automation, and creating complex, high-quality products.

These special zones are becoming magnets for new global money, creating powerful manufacturing FDI hubs. They offer foreign companies a complete package: skilled workers, modern infrastructure, and a helpful local government. They take away a lot of the risk and guesswork from setting up shop in a new country. By making it easy and smart to invest, these hubs are shaping where the world’s goods will be made next. But how exactly do these advanced zones convince global companies to spend billions right on their doorstep?

What are advanced manufacturing hubs and why do they matter for foreign companies?

An advanced manufacturing hub is a focused area, often a special industrial park or zone, designed specifically for modern production. It is a step above the traditional factory district. Instead of just having buildings and roads, these hubs are packed with next-generation tools and systems. We are talking about things like 3D printing labs, testing facilities for new materials, and smart factories where machines talk to each other.

These hubs matter greatly to foreign companies because they solve big problems. If a company wants to build a complex product, like a specialized medical device or an electric car part, they need more than just space. They need an environment where they can innovate and grow quickly. The hub provides a ready-made ecosystem. This means they can find the right suppliers nearby, hire people trained in the newest skills, and get their products to market faster. A foreign investor can set up a new plant and know that the basic high-tech needs are already taken care of.

The entire idea is to lower the effort and risk for the investor. Imagine a German car company wanting to build an engine plant in Asia. Building that kind of advanced facility from scratch in a new country can be very difficult. But if they invest in a well-established manufacturing FDI hub, they can skip many of those headaches. They instantly gain access to high-speed internet, reliable power grids, specialized training centers, and a cluster of related businesses. This makes the investment decision much easier and safer, which is why these places are seeing a lot of new FDI. They are the new gold standard for industrial growth.

How do advanced manufacturing hubs make it easier for foreign companies to invest?

Advanced manufacturing hubs reduce the barriers to entry for global businesses. A big part of this is simplifying the official, or “red tape,” process. When a company decides to invest in a foreign country, they face many steps: getting permits, registering the business, dealing with import/export rules, and following labor laws. This can take months or even years and cost a lot of money.

Many of these hubs are set up as special economic zones (SEZs). Within these zones, the local government often offers a “one-stop shop” for investors. This means a foreign company can go to a single office to handle all the paperwork instead of visiting 15 different government departments. This speed and simplicity save the company time and money, making the location instantly more attractive.

Another major benefit is the set of financial incentives offered. To attract high-value foreign investment, these hubs often provide tax breaks. A company might pay no corporate tax for the first few years or get a discount on taxes for a long period. They might also receive grants or subsidies to train local workers in the new, advanced skills needed for the factory. These financial benefits act as a huge extra bonus, often tipping the scales in favor of investing in the hub over a cheaper, less organized location. The combination of easy setup and financial rewards is what truly drives FDI to these specialized manufacturing FDI hubs.

- Tax Incentives: Offering lower or zero corporate tax for a set number of years.

- Streamlined Regulations: Creating a single, easy process for business registration and permits.

- Infrastructure: Ensuring top-tier physical necessities like ultra-reliable power and high-speed fiber-optic cables.

Why are skilled workers and R&D facilities so important for manufacturing FDI hubs?

Foreign companies looking to invest in advanced manufacturing are not just looking for bodies to fill jobs. They are looking for highly skilled talent. They need people who can program robots, fix complex automated machinery, manage advanced supply chains, and design new products. This is where the training and education offered by manufacturing FDI hubs become key selling points.

Many advanced hubs work directly with local universities and technical schools. They help design training programs that teach the specific skills the new factories will need. For example, if a hub is focusing on aerospace parts, the local college will offer a course on composite material manufacturing. This creates a ready-made pool of talent. When a foreign company sees that it can hire 50 specialized engineers right away, the hub becomes a much more appealing investment location.

In addition to workers, research and development (R&D) centers are vital. Modern manufacturing is always changing; companies need to innovate to stay competitive. A hub that hosts shared R&D facilities or works closely with university research labs provides a huge benefit. A foreign company can use a shared, high-cost testing lab without having to build its own. This saves the investor money and gives them access to the latest research and ideas. This focus on both current skills and future innovation makes these hubs true magnets for quality FDI. The foreign investor is not just buying land; they are buying into a system that guarantees talent and technological growth.

How does the “clustering” effect make advanced hubs more attractive to global investors?

The “clustering” effect is a major reason why advanced manufacturing FDI hubs are so successful. The idea is simple: when similar or related companies are all located in the same geographic area, they all benefit. This creates a powerful network that is very attractive to foreign investors.

Think of it like this: if one major car maker decides to build a factory in a hub, all the companies that supply parts to that car maker will want to move there too. They want to be close to their main customer to deliver parts faster, communicate easily, and solve problems quickly. So, an investment by a single large company often pulls along a dozen smaller, specialized foreign suppliers. This creates a thick concentration, or cluster, of related industries.

This concentration brings massive benefits. For example, if a company needs a special type of metal part, they don’t have to ship it from across the country or the world. A specialized metal supplier is likely already in the same hub, sometimes just a few streets away. This lowers shipping costs, makes the supply chain much faster, and reduces the risk of delays. The presence of so many other related businesses means that the hub can support itself. Foreign investors see this existing cluster of companies as a sign of success and a guarantee that they will find everything they need to operate efficiently. This magnetic effect, where one investment attracts many more, is a hallmark of successful manufacturing FDI hubs. It proves that the whole is greater than the sum of its parts.

Why is reliable infrastructure a bigger factor than low wages in attracting advanced manufacturing FDI?

In the past, foreign companies mainly looked for places with the lowest possible wages. While low labor cost is still a factor, it is no longer the most important thing for advanced manufacturing. Modern factories rely heavily on advanced infrastructure, and a breakdown in that can cost more than any wage savings.

An advanced factory uses high-end, complex machinery that runs on automation. If the power goes out, even for a few minutes, it can ruin a batch of high-value goods, damage expensive equipment, and stop production. A hub that promises reliable and stable power 24 hours a day, 7 days a week, is far more appealing than a location with cheap labor but shaky electricity. Foreign companies will pay a little more in wages to avoid the massive losses that come from infrastructure failure.

The same goes for digital infrastructure. Modern manufacturing relies on real-time data flow. Machines and computers constantly talk to each other and to the main office thousands of miles away. This requires fast, rock-solid high-speed internet and secure data lines. A well-designed manufacturing hub guarantees this level of digital service. In fact, for a factory where a robot does most of the work, the cost of the raw materials, the machinery, and the power are much greater than the wages of the few highly skilled technicians who oversee the process. Therefore, guaranteeing operational efficiency through excellent infrastructure has become the number one priority for attracting high-quality FDI.

- Power Reliability: Essential for automated machinery to prevent costly shutdowns and damage.

- Digital Connectivity: Necessary for data transfer, remote monitoring, and complex supply chain management.

- Logistics: World-class ports, airports, and highways ensure products can quickly reach global markets.

How do successful manufacturing FDI hubs manage risk and ensure legal fairness for foreign investors?

When a foreign company invests billions of dollars in a new country, its biggest fear is often risk and uncertainty. They worry about changes in the law, political instability, or the government suddenly changing the rules of the game. Successful manufacturing FDI hubs work hard to lower these non-business risks, making the investment feel secure.

One of the most important things they offer is legal and regulatory stability. This means the rules and laws that apply to the hub are clear, published, and guaranteed not to change overnight. Many hubs have special legal frameworks that protect foreign investments. They might offer clear, defined processes for settling disagreements, such as through international arbitration, rather than just using the local court system. This gives foreign investors confidence that their money is protected and that they will be treated fairly.

Also, many hubs offer political stability through long-term government support. The local and national governments make a clear, public commitment to the hub, showing that it is a priority. This reassures investors that the project will continue even if a new political party comes into power. By building a reputation for being safe, predictable, and fair, these advanced zones attract not just money, but also the world’s most cautious and high-value investors. The creation of a safe and fair operating environment is as crucial as the tax breaks and the infrastructure in the competition for global FDI.

Conclusion

The global competition for Foreign Direct Investment (FDI) is more intense than ever. Countries are realizing that simply offering cheap labor is no longer enough to win the best projects. The future of manufacturing is high-tech, precise, and highly automated. This is why the rise of the advanced manufacturing hub is such a major trend.

These specialized zones offer foreign investors a complete, low-risk, and high-value proposition. They combine world-class infrastructure, a ready supply of skilled workers, simplified government processes, and financial incentives. They create powerful industrial clusters where companies benefit from being near their suppliers and competitors. By focusing on creating environments of high efficiency and low uncertainty, these manufacturing FDI hubs are successfully drawing in billions of dollars and defining where the next generation of products will be built. This shift shows that the quality of the investment environment now matters more than the quantity of workers.

What specific steps can a region take today to transition from a simple factory area to a true, advanced manufacturing hub of the future?

FAQs – People Also Ask

1. What is the difference between an industrial park and a manufacturing FDI hub?

An industrial park is simply a piece of land zoned for factories. A manufacturing FDI hub is much more advanced; it is a planned ecosystem that includes specialized infrastructure, training centers, shared R&D facilities, and special legal or tax incentives designed to attract high-value foreign companies.

2. How does a manufacturing hub help smaller local businesses?

When large foreign companies move into a hub, they need many local services and suppliers. This creates a huge demand for things like local transport, catering, specialized maintenance, and professional services, which helps existing local businesses grow and new small businesses to start up.

3. Why do countries give tax breaks to foreign companies in these hubs?

Governments offer tax breaks as an upfront incentive. The idea is that while the country loses some tax revenue now, the long-term benefits of the investment, such as creating thousands of high-wage jobs and bringing in new technology and export revenue, are far greater and last much longer.

4. What types of industries are usually found in an advanced manufacturing hub?

Advanced hubs typically focus on high-value and high-tech sectors. Common industries include aerospace components, electric vehicle manufacturing and parts, medical devices, specialized electronics, advanced machinery, and precision engineering.

5. Does FDI in these hubs only create factory jobs?

No. While many jobs are in production, FDI also creates a wide range of high-skilled, white-collar jobs. These include research scientists, software engineers, accountants, supply chain managers, human resources specialists, and specialized technical trainers.

6. What role does automation play in the success of a manufacturing FDI hub?

Automation is central. These hubs are designed for smart factories that use robots and computer-controlled systems. This focus on automation allows the factories to achieve high quality and consistency, which is a major factor that attracts high-end foreign investors looking for precision.

7. How do foreign companies ensure a skilled workforce is available?

Foreign companies often partner directly with local governments, technical colleges, and universities located near the hub. They help design the curriculum and sometimes donate equipment to ensure students are being trained on the exact skills and machinery the company will use in its new factory.

8. What is meant by a “one-stop shop” service for investors?

A “one-stop shop” is a single administrative office within the hub where a foreign company can handle all the necessary government paperwork. This includes business registration, permits, environmental approvals, and tax applications, which simplifies the whole process and saves the investor time.

9. How do manufacturing hubs protect the environment?

Many advanced hubs have strict environmental standards built into their rules. They often require companies to use newer, cleaner technologies and adhere to modern waste treatment and energy efficiency standards. This commitment to sustainability is part of the high-quality image that attracts responsible global investors.

10. Do manufacturing FDI hubs only benefit developed countries?

No, many successful hubs are found in developing countries that are making a strong push to move away from low-cost, low-skill production. By creating these advanced zones, developing nations can attract better-paying jobs, gain new technologies, and become stronger players in the global economy.